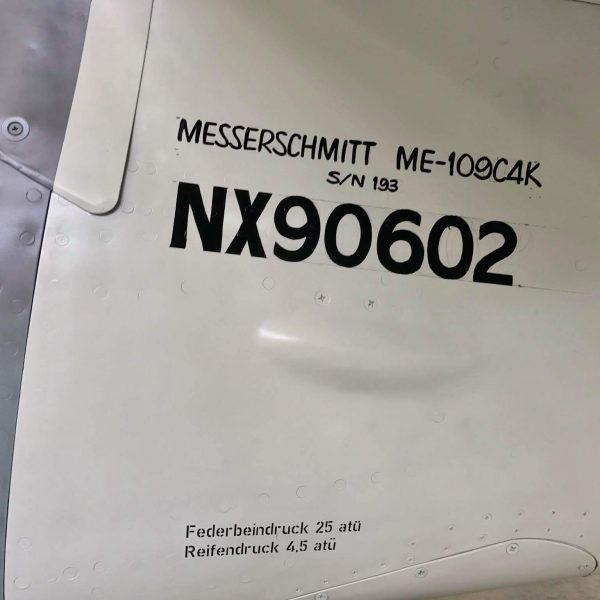

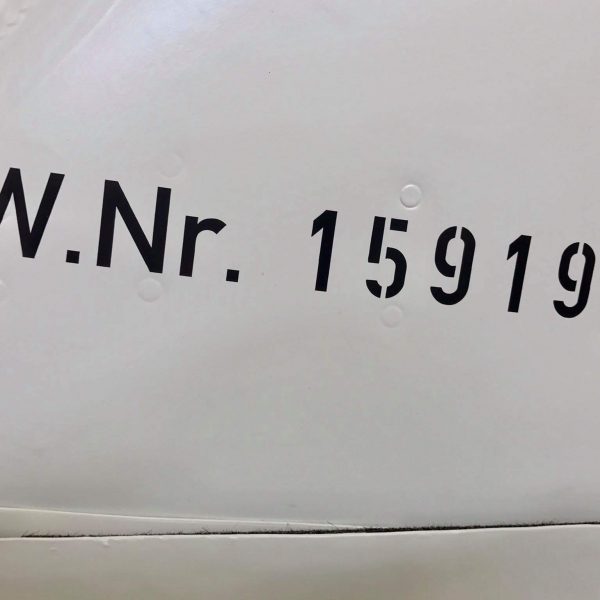

Messerschmitt Bf-109 G-10/Hispano Aviación Buchón HA-1112-M1L

https://www.facebook.com/

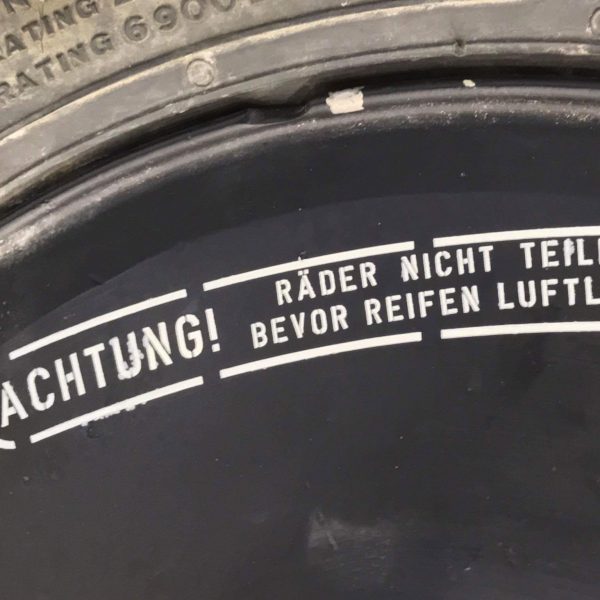

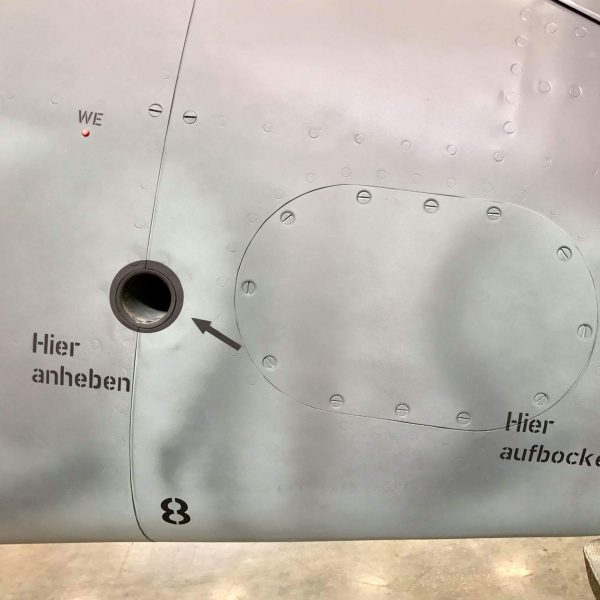

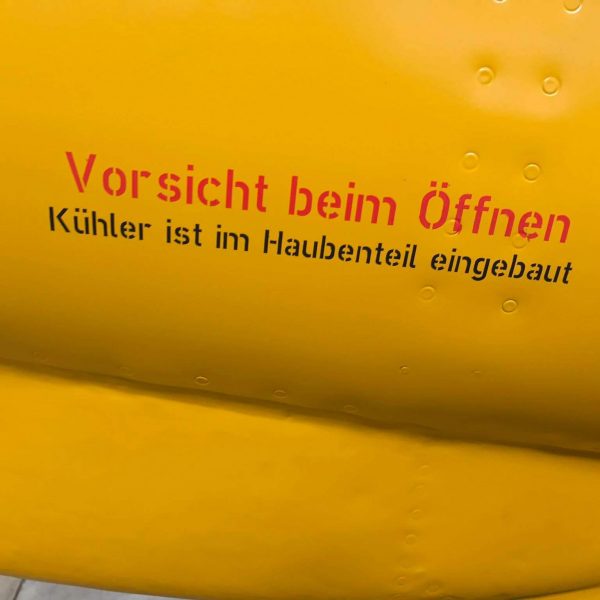

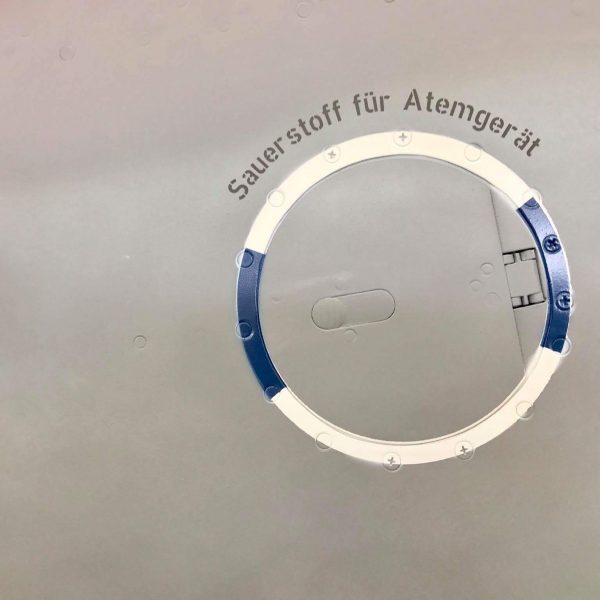

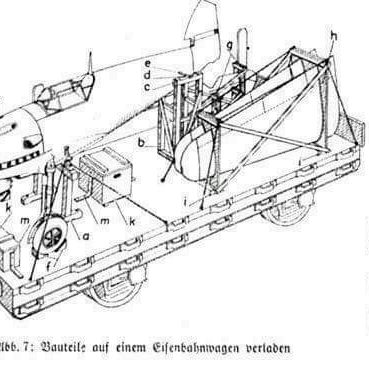

During its entire production run, the Bf-109 was also built by Erla, Arado, Focke-Wulf, Fieseler (the Erla factories built approximately one-third of the 109’s produced between 1937-45), and Hispano Aviación under a 1943 license from Messerschmitt. Designed with a Daimler-Benz DB 605D inverted V-12 engine. The landing gear were attached to the fuselage by a forging of electron magnesium alloy at the firewall aft of the engine mount so that the wings could be removed without any additional supports for the fuselage for ease of maintenance – and for ease of rail transport if need be (see photo and diagram). Because of the narrow fuselage, the gear struts are splayed outwards. The wheels are mounted “crooked” at about a 25 degree camber and as a result, tend to turn inwards making them roll straight. Because of the torque created by the engine, the left landing gear strut is given increased pressure (equivalent to 100 PSI) so when parked, the aircraft does not have a level stance. The wheel wells are lined with canvas, and there are no inner wheel well doors since the wings of the aircraft were not fitted with a mechanism for a clamshell arrangement. Armed with two 13 mm machine guns atop the cowling and a 20 mm or 30 mm cannon that was mounted through a sealed tube between the engine’s cylinder banks. The reduction gear offset the propeller shaft away from the crankshaft so the tube for the cannon sits down in the inverted-V of the cylinder banks. The cannon barrel fit the entire length of the engine block to a point just past the propeller spinner. The automatic, spring-loaded movable slats on the wing leading edges droop down at lower speeds for improved handling, and the ailerons drooped when the flaps were lowered, increasing flap area (versus fixed “slots” on the Fieseler “Storch” for example).